Sustainable Synthetic Fiber Machinery for Textiles Synthetic fiber machinery is a critical foundation for modern textile manufacturing in Europe, where sustainability, precision, and production consistency are essential requirements. European manufacturers increasingly rely on advanced synthetic fiber machinery to produce high-quality...

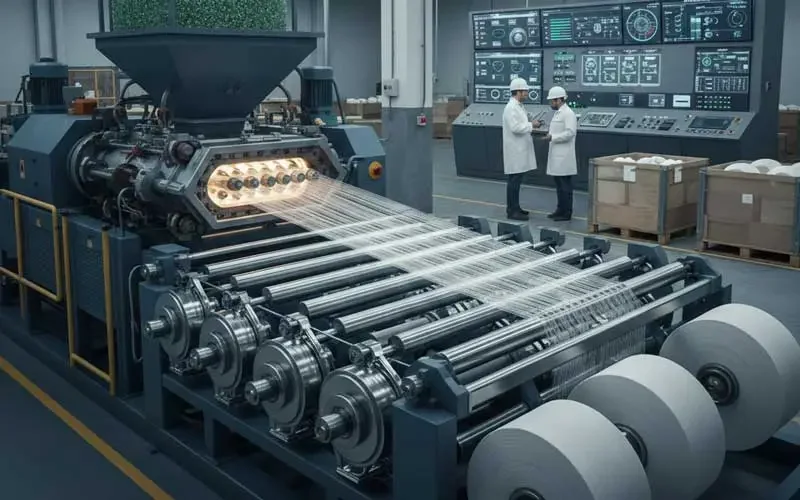

Synthetic fiber machinery is a critical foundation for modern textile manufacturing in Europe, where sustainability, precision, and production consistency are essential requirements. European manufacturers increasingly rely on advanced synthetic fiber machinery to produce high-quality fibers from both virgin and recycled raw materials, particularly recycled PET. A well-engineered synthetic fiber machinery system ensures stable fiber properties such as strength, uniformity, and durability. These characteristics are vital for industries producing textiles, industrial fabrics, and technical fibers. Synthetic fiber machinery involves multiple interconnected stages, including extrusion, spinning, stretching, and winding. Each stage must operate with precise control to prevent defects and material waste.

Synthetic fiber machinery plays a central role in supporting Europe’s transition toward sustainable and circular textile production. As regulations tighten and consumer demand for eco-friendly products grows, manufacturers must adopt machinery capable of processing recycled materials without compromising quality. Synthetic fiber machinery enables the efficient conversion of recycled PET granules into usable fibers for textiles and industrial applications. European producers require machinery that meets strict performance standards while maintaining energy efficiency and low emissions. Advanced synthetic fiber machinery ensures consistent fiber dimensions, controlled molecular orientation, and stable production speeds.

The engineering principles behind synthetic fiber machinery determine its operational stability and output quality. Precision mechanical components, advanced control systems, and robust structural design are essential for continuous industrial operation. Synthetic fiber machinery must maintain consistent temperature and tension control throughout the production line to ensure fiber uniformity. Any instability can lead to defects such as uneven thickness or reduced tensile strength. Modular design is another critical principle, allowing synthetic fiber machinery to be adapted or expanded based on production requirements. Engineering teams with hands-on manufacturing and repair experience design synthetic fiber machinery with durability and serviceability in mind.

Synthetic fiber machinery is most effective when seamlessly integrated with upstream recycling and granulation systems. For recycled PET applications, material quality entering the synthetic fiber machinery directly affects fiber performance. Proper integration ensures consistent material flow, stable viscosity, and controlled processing conditions. European facilities prioritize integrated production lines to maximize efficiency and reduce operational complexity. Negin Bartar Banaei has developed such integrated systems by combining knowledge of PET recycling, granule production, and fiber machinery. This holistic approach ensures that synthetic fiber machinery operates as part of a unified, high-performance production environment.

Synthetic fiber machinery designed for recycled PET applications must meet higher technical demands than systems using virgin materials. Recycled PET presents variability in molecular weight and contamination levels, requiring advanced process control. Synthetic fiber machinery equipped with precise filtration, degassing, and temperature regulation ensures that fibers produced from recycled PET meet European quality standards. These systems allow manufacturers to achieve consistent fiber properties suitable for textiles, nonwovens, and industrial uses. Engineering-focused manufacturers design synthetic fiber machinery to stabilize processing conditions and compensate for material variability.

The long-term success of synthetic fiber machinery depends not only on its initial performance but also on its maintainability. Suppliers with repair experience design synthetic fiber machinery that allows easy access to critical components and predictable maintenance schedules. This reduces downtime and lowers overall operating costs. Negin Bartar Banaei began its industrial operations in 2009 with a focus on manufacturing and repairing recycling and synthetic fiber machinery. This background ensures that design decisions are informed by real-world operational challenges. Synthetic fiber machinery built with repairability in mind offers greater durability and longer service life.

Synthetic fiber machinery intended for global markets must adapt to diverse production conditions and regulatory environments. Manufacturers with international experience understand how to design systems that remain stable across varying input materials and operational standards. Negin Bartar Banaei has supplied machinery to Iran and neighboring countries such as Iraq, Turkmenistan, and Armenia, gaining valuable insight into diverse industrial settings. This experience strengthens engineering judgment and system flexibility. Synthetic fiber machinery designed with adjustable parameters and scalable capacity is well-suited for European manufacturers seeking future-proof solutions.

Choosing a synthetic fiber machinery supplier is a strategic decision for European manufacturers. Beyond technical specifications, buyers should evaluate engineering expertise, customization capability, and long-term technical support. Synthetic fiber machinery represents a significant investment that directly affects product quality and production efficiency. Suppliers with in-house engineering teams and manufacturing facilities provide greater reliability and transparency. Negin Bartar Banaei delivers engineered solutions grounded in practical manufacturing and repair experience, ensuring that synthetic fiber machinery aligns with real industrial requirements.

Synthetic fiber machinery technology continues to advance as European industries pursue higher efficiency and sustainability. Automation, digital monitoring, and energy optimization are becoming standard features in modern production lines. Advanced synthetic fiber machinery integrates smart control systems that allow real-time process monitoring and optimization. These technologies help manufacturers reduce waste, improve consistency, and meet environmental targets. The growing use of recycled materials further drives innovation in synthetic fiber machinery design. Future-ready synthetic fiber machinery provides European producers with long-term competitiveness and operational resilience.

Contact with Negin Bartar Banaei

Do you have any questions?

Contact us now so our experts can guide you.

درحال ورود...